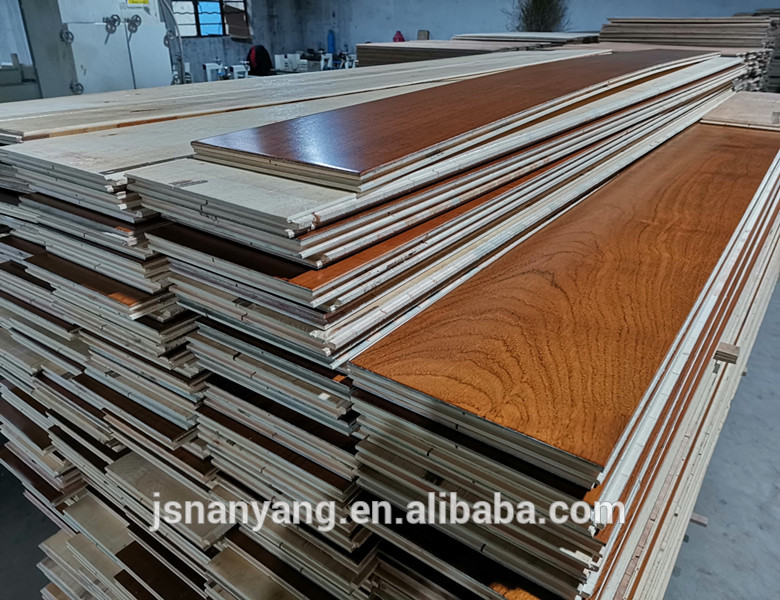

Teak color stained engineered wood flooring

Top Veneer Materials | Teak |

Structure | 3-layer |

Surface | Smooth, UV Lacquered |

Size | 1860*190*15/4 or as your customized |

Thickness of the Top Veneer | 3mm, 4mm |

Grade | AB, |

Air-dry Density | 0.8g/cm3 |

Moisture content | 8-12%( or as per your requirement) |

Gloss level | 25% +/-5% |

Formaldehyde Release | E1 |

Joints | 4 sides T&G |

End and Edge | Square or micro beveled |

Installation | Nail down, glue down or stape down |

Package | Carton and Pallet |

1.Product Picture:

Any colors,any logo acceptable,free sample service,leave an inquiry to know more details about Price,Packing,Shipping and Discount.

2.Production Process:

3.Testing Tools:

4.Package & Transportation:

5.Certifications:

6.Project Cases:

7.Advantages:

Raw materials advantages | Ø First-hand forest resources Ø Precious timber species are carefully selected from all over the world. |

Technique advantages | Ø Controlling to Moisture content is in the whole production process. Ø The big timber conditioning room eliminates the inherent problem of shrinkage and distortion. Ø Skillful agglutination technique, 1,600 meric ton heavy-duty pressing facility and enviromental glue used. Ø Advanced skill in making T&G and right angle, plane variation of installed flooring within 0.05mm. Ø Perfect coating process with 6 bottom layers, 2 face layers with aluminum oxide additional. |

Equipment advantages | Ø Advanced flooring line imported from Gemany Ø International leading intelligent timber drying equipment Ø Intelligent flooring coating shower line. |

Products advantages | Ø Various solid, 3-layer and muli-layer engineered wood flooring are for your choice Ø Waterproof solid wood flooring has registered several national patents Ø Handscraped classical distressed wood flooring are available Ø Professional sports flooring is highly rubbing, scratch and impact resistable. |